Environmental monitoring involves the systematic collection of data on physical parameters such as air quality, noise levels, vibration, and water quality to understand both human impact and the natural state of our environment.

It helps ensure compliance with regulations, identify potential hazards, and support informed decision-making to protect both human health and natural ecosystems. By tracking environmental changes over time, we can better manage resources, mitigate risks, and safeguard the sustainability of our surroundings.

Remote environmental monitoring is the use of automated sensors and communication technology to collect and transmit real-time data on environmental conditions—such as air quality, noise, vibration, and water quality—without the need for direct human intervention.

- Real-Time Data – Provides continuous monitoring for immediate detection of environmental changes.

- Cost-Effective – Reduces the need for manual site visits and data collection.

- Hard-to-Reach Areas – Enables monitoring in remote or hazardous locations.

- Regulatory Compliance – Ensures industries meet environmental standards efficiently.

This technology is widely used in construction, mining, infrastructure, and environmental conservation to improve decision-making and minimize environmental impact.

To keep costs low, integrate the latest technology, and maintain full control over our systems, we have developed our solutions in-house.

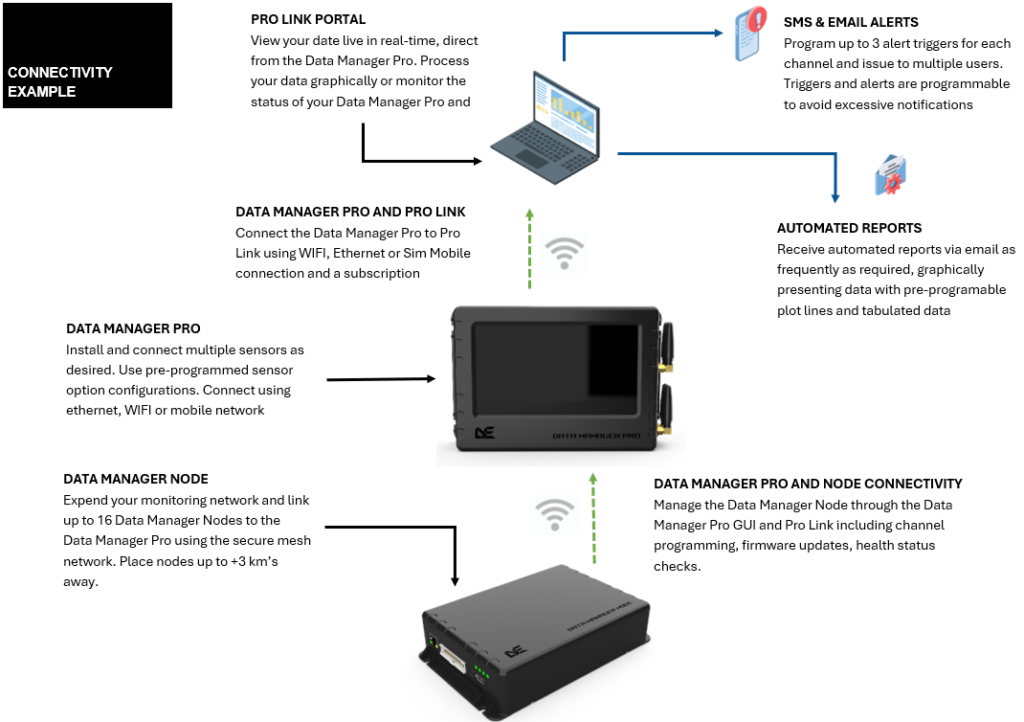

Together with our sister company, LYE Instruments, we developed the Data Manager Series which consists of the Data Manager Pro and Data Manager Node. The Data Manager Pro is the powerhouse of the system, equipped with full processing capabilities and connectivity to Pro Link (our online portal).

The Node acts as an extension of the Pro, designed for hard-to-reach areas where additional sensor coverage is needed. We’ve engineered our systems for reliability, connectivity, data accuracy, scalability, and ease of use, making them ideal for remote monitoring applications.

At the core of our system, the Data Manager Pro serves as the central hub, processing and transmitting sensor data to users via Pro Link and a 7-inch touchscreen graphical user interface (GUI).

The Data Manager Node provides similar sensor connectivity and pre-programmed functionality as the Pro but lacks the touchscreen, modem, and direct connection to the Client Portal. It must be paired with a Data Manager Pro to operate.

Pro Link is ECEM’s online portal that connects directly to the Data Manager Pro, enabling full remote monitoring, control, and data management.

The Data Manager Pro processes all incoming sensor data and securely transmits it to Pro Link for real-time alerting, analysis, and reporting. This ensures users can act swiftly based on live insights from the field.

Unlike basic loggers, Pro Link enables two-way communication with the Data Manager Pro — making it a true remote-access platform. All settings on the Data Manager Pro can be programmed through Pro Link, eliminating the need for on-site configuration and saving valuable time and cost in the field.

Find out more about the Data Manger Pro and Node hardware in our blog post here.

Key Features of Pro Link:

- Dashboard view of all registered stations, including:

- System health status

- Daily alerts

- Live weather updates

- Interactive map with instant data and location markers

- Real-time data visualisation for all 16 channels:

- Displayed as tables, graphs, or dynamic gauges

- Fully customisable views

- Channel-level access for:

- Calibration

- Sensor checks

- Programming alerts and thresholds

- 2 programmable relay controls

- Node management:

- View all registered Nodes and their health status

- Automated reports:

- Customisable scheduling and data formats

- Alert register with Event Vision:

- Recorded 5-second video clips for triggered events

- Control panel:

- System diagnostics

- Over-the-air (OTA) firmware updates

- Data download for offline analysis and archival

Pro Link is available via subscription and includes secure server hosting and user access management.

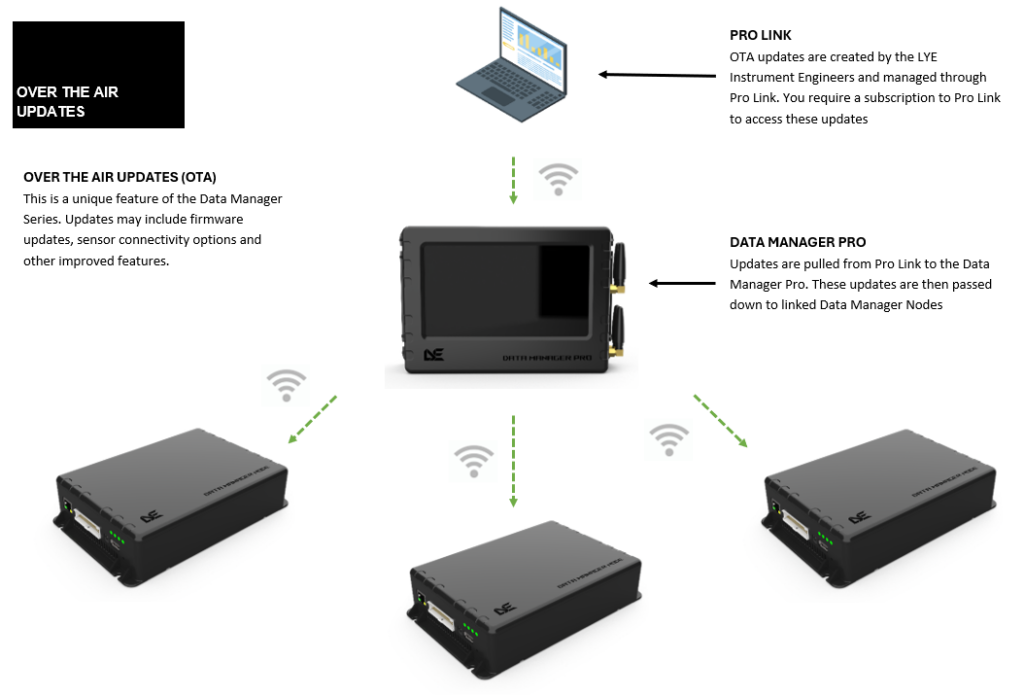

The Data Manager Pro and Nodes software streamlines update deployment by offering seamless Over the Air (OTA) updates. These are accessible with just a few taps on the Data Manager Pro’s intuitive graphical user interface or via Pro Link. We commit to delivering software updates that not only enhance sensor connectivity and security but also fix potential bugs and improve the overall user experience.

By subscribing to Pro Link, you access the full suite of OTA update capabilities. Your Data Manager Pro only needs a stable internet connection, achievable through an ethernet cable, WiFi, or its onboard modem. This process does away with the need to tether devices to a computer, manually download update files, or navigate cumbersome third-party software.

Additionally, the innovation extends beyond the Data Manager Pro. Any Nodes connected to your system also receive hassle-free, automatic updates, keeping your entire network at the cutting edge without further effort on your part.

For our standard fleet of dust, air quality, noise, and vibration sensors, we provide factory calibration certificates. These sensors are regularly verified using industry-calibrated tools, with calibration certificates available upon request. This calibration method is suitable for most applications, such as construction nuisance monitoring.

If more advanced sensors are required or if specific calibration certificates are needed, we send these to a third party for calibration to NATA standards. This service incurs an additional fee.

You can configure each channel with up to three levels of alerts, tailoring the system to meet your specific needs.

For every level of alert, you can:

- A customisable mix with minimum and maximum trigger values

- Send SMS and email notifications

- Assign different recipients for each alert level, facilitating issue escalation

- Control alert repetitions through specific events or time delays

- Manage alerts by setting limits on the number per hour or day

- Schedule alert reception times to avoid disruptions, such as outside business hours

For vibration monitoring, you can do all the above plus we have enabled the following alert options:

- DIN4150: Tailored for vibration limits according to the DIN4150 standard

- BS7385-2: Designed for vibration limits in line with the BS7385-2 standard

Pro Link also includes programmable alerts for low power supply, low memory, and network connection loss, keeping you informed of any potential issues.

Our Data Manager Pro is programmed to take 5 second video with audio clips onsite using the onboard camera, and pair it with alerts detected on Pro Link. These videos are attached to the Alert Log for quick and easy viewing.

This is helpful on projects sites when trying to determine the source of a triggered event. No more guessing! The video can be viewed in your browser or downloaded and shared.

Our turn key solutions come with a 360 degree adjustable camera installed.

Our automated reporting has been designed to keep the user informed and reduce the need for 3rd parties to manage and process your data. Using Pro Link (online portal) you can:

- Easily set up automated reports for regular intervals (daily, weekly, etc.)

- Choose which channel data to report and enhance it with plot lines as needed

- Designate report recipients

- Engage with both graphical and tabulated data within the reports

- View triggered alerts

- Save significant time and resources on routine reporting tasks

The dust (air quality) sensor is an Optical Particle Counter (OPC) sensor with the addition of an air inlet. The sensor is suitable for a wide range of air quality monitoring including dust on construction sites. Calibration can be adjusted using a k-factor via the Pro Link (online) portal. Its key features include:

- Measures PM1, PM2.5, PM10

- Particle range of 0.35 to 40 um spherical equivalent size (based on RI of 1.5+i0)

- Total flow rate max is 5.5 L/min

- Sample flow rate of 210 mL/min

- Max particle count rate of 10,000 particles/sec

- Detection limits (PM10) of 0.01 ug/m3 to 1 500 mg/m3

- Capability to measure up to 2,000 ug/m3

- Particle size measurements are comparable to industry standard air particulate measuring instruments

We use a Class 2 environmental noise sensor. Its suitable for environmental noise monitoring on construction sites for example to help manage noise related risks. Complies with requirements of IEC 61672 for Class 2.

We use a precision MEMS based sensor capable of monitoring Vibration, Angle, and Tilt, tailored specifically for the Data Manager Pro. Engineered for applications such as construction vibration monitoring, as well as tasks that demand measurements of infrastructure tilt or angle. Its versatile, robust and efficient in capturing critical data across a variety of settings. Key features include:

- Dynamic Kalman filter algorithm and high-performance microprocessor operating up to 200Hz (samples per second)

- Automatic gravity compensation algorithm

- Comes in tough metal enclosure designed to operate in harsh environments

- Peak Particle Velocity (PPV) (mm/s) of each individual X,Y,Z axis and frequency (Hz)

- Vector PPV (mm/s) and frequency (Hz) combined axis

- Angle of each individual X,Y,Z axis – axis can be zeroed to measure tilt from reference point

- All options can be measured simultaneously

- Programmable installation position (horizontal or vertical)

- Programmable low and high cut filters (vibration channel only)

- Option to zero X, Y and Z axis (angle channel only)

- Adjustable sampling bandwidth and sampling frequency

- Choose between 6 or 9 axis degrees of freedom if in magnetically noisy environments

We are based on the Gold Coast in Queensland, Australia. We can service customers in person located in Queensland, New South Wales, Victoria and South Australia. However, if you are located elsewhere or international, don’t worry, we can ship a monitoring package you door. Our systems are easy to install and operate.

Want to find out more?

Sign up to our free newsletter here